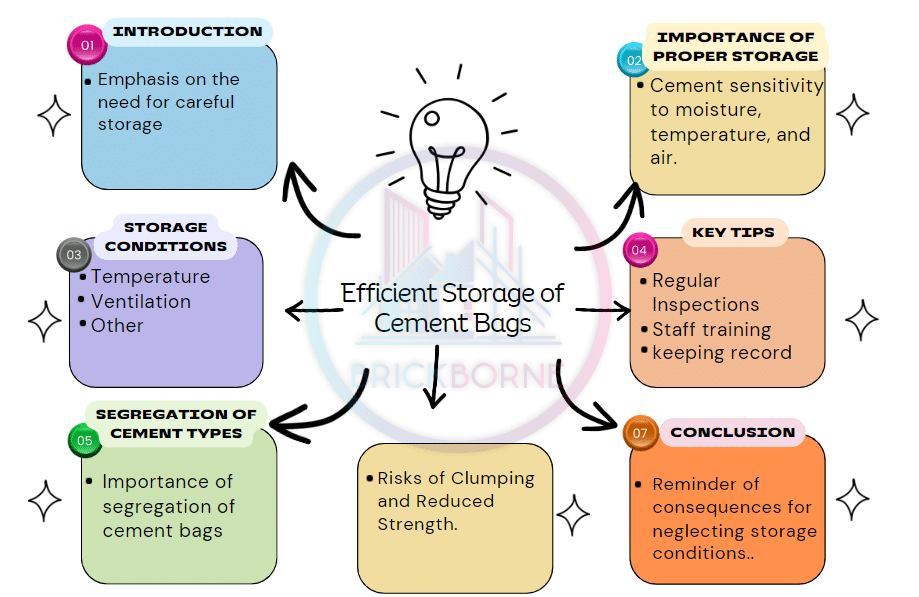

The construction industry commonly uses cement as a material. It acts as a binding material in concrete. Thus, the strength of concrete buildings greatly depends on the quality of the cement. Cement should be carefully dealt with during its stages i.e., production, storage, handling, and mixing. In this blog, we will cover one aspect which is the storage of cement bags. You’ll learn about the efficient storage of cement bags, the importance of proper storage conditions, and tips to enhance cement efficiency to ensure good quality concrete for your home.

Importance of Proper Storage of Cement:

Cement is an important element in concrete. The strength of concrete greatly depends on the quality of cement. But, the quality of cement is affected by the way cement is stored. Cement is a very sensitive material that is easily affected by different environmental factors such as:

- Moisture

- Temperature

- Air Exposure

Improper storage of cement can lead to different issues such as clumping and reduced strength. This reduction in strength can compromise structural integrity in the final construction stage. Therefore, it is important to save cement, especially from moisture.

Standard Warehouse Storage Conditions for Cement:

- Maintaining the temperature is crucial for the cement warehouse. Fluctuations in temperature can cause condensation inside the bags leading to clumping of the cement. It is best to keep the warehouse at a temperature avoiding heat or cold.

- Firstly, to prevent moisture buildup, proper ventilation is necessary. Good airflow helps maintain humidity levels reducing the risk of cement absorbing moisture and losing its quality. Ventilation also helps prevent lumps from forming in stored cement.

- Secondly, efficient storage relies on the stacking and palletizing of cement bags. Arranging bags on pallets allows air circulation. Prevents contact with the floor. When stacking it’s important to avoid putting pressure on the bags to minimize deformation risks.

- Thirdly, protecting cement bags from sunlight, rain, and other weather elements is crucial. Although cement is durable, exposure to these elements can damage its surface which will compromise its quality. To ensure protection, suitable covers or placing bags in sheltered areas should be considered.

- It’s essential to consider segregation when storing different types of cement as they may have storage requirements. It is important to separate kinds of cement, to avoid any cross-contamination. By labeling and organizing them, we can ensure that the appropriate type of cement is utilized for each project.

Key Tips for Efficient Storage of Cement:

- Perform inspections to regularly check the storage conditions.

- Keep track of outgoing cement bags. In this way, older stock will be used first preventing the cement from aging.

- Provide training to warehouse staff.

Conclusion:

You may have noticed that storage of cement is way than just stacking bags on shelves. It involves careful consideration of different factors which are discussed above. Ignoring those factors can have far-reaching consequences. Follow the proper storage conditions and contribute towards enhancing the quality and life of cement.

Brickborne believes in accuracy and time construction without wastage of resources. We believe in economical and sustainable construction. With the advancing world, software is here to assist us in the construction field. Brickborne provides construction drawings as per codes of the region, 3D modeling, rendering, and animation walkthroughs of both interior and exterior, and quantity surveying and cost estimation. Choose us to change your dreams into reality as we say, Brickborne- We Design Your Ideas!