As the world is advancing, the construction industry is advancing as well. One of the most significant advancements in the construction industry is the ” Automated Bricklaying Machine” or ” Robot Brick Laying Machine. Furthermore, this blog sheds light on a brief explanation of the Automated Bricklaying Machine, its types, advantages and disadvantages of robot brick laying machine and the cost of brick laying machines.

What is an Automated Brick Laying Machine?

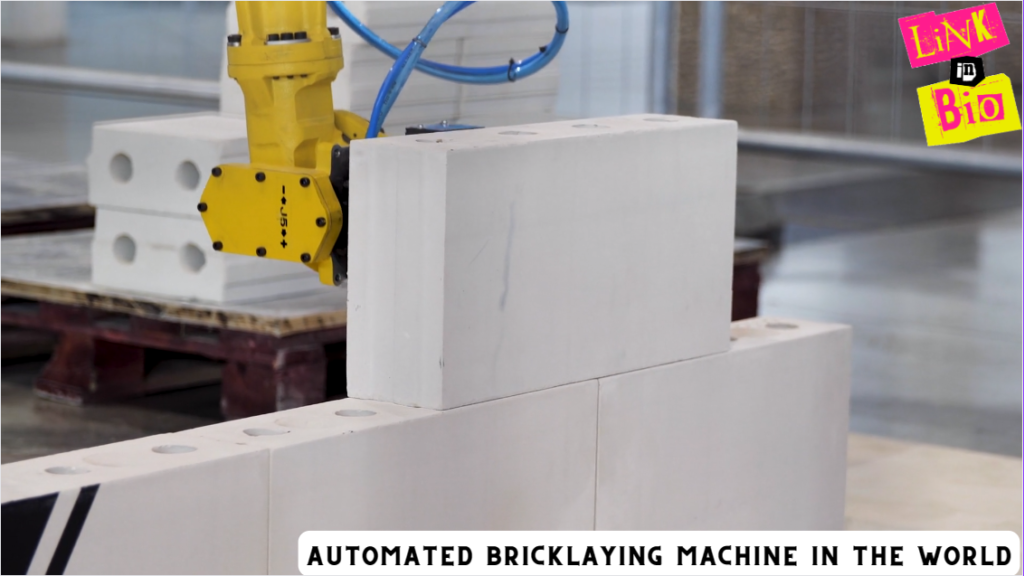

The automated brick-laying machine also known as a robot brick-laying machine or bricklaying drone is a machine that is designed to lay bricks, automatically. Furthermore, this machine uses a combination of sensors, robotic arms, and software to develop brick structures with precision and accuracy. These brick-laying robots can act 24/7. Moreover, the automatic brick layer machine has the ability to read digital building plans, calculate the number of bricks required and lay them at a rapid pace.

What are the Types of Automated Brick Laying Machine

Some of the most frequently used types of automated brick-laying machines are as follows;

SAM100

It is a state-of-the-art machine that is designed to automate the bricklaying process. It is a fully automated system that can lay up to 1000 bricks per hour, which is equivalent to the work of four to six masons. Moreover, the machine has a robotic arm. This arm picks the bricks from the feeding system and places them in the required position.

Hadrian X

It is a robot that uses a 3D CAD model of a building to lay bricks with high precision and accuracy. Fastbrick Robotics, an Australian-based company developed it. Furthermore, the machine is designed to work on-site, making it perfect for large-scale construction projects.

Hadrian X uses a telescopic boom that reaches up to 30 feet high and can lay bricks at a rate of 1,000 per hour. A single person operates it and loads the machine with bricks, mortar, and other necessary materials. Furthermore, the machine then uses its 3D CAD model to determine the precise location of each brick and lays them accordingly.

Tiger Stone

The Tiger Stone automated bricklaying machine is a specialized piece of equipment designed to automate the process of laying bricks. It uses a conveyor belt to feed bricks to the machine, which then places them in the desired pattern using a laser-guided system. Furthermore, it can lay up to 400 square meters of brick road per day, which is significantly faster than manual labor.

Advantages and Disadvantages of Automated Brick Laying Machine

| Advantages | Disadvantages |

| Increased Speed and Efficiency: It can lay bricks much faster than human workers. | High Initial Cost: They can be expensive to purchase or rent. |

| Greater Accuracy: These machines are programmed to lay bricks with a high degree of precision. | Limited Flexibility: They lay bricks in a specific manner eventually, reducing the usage. |

| Improved Safety: They do heavy lifting and manual labor which is often required when laying bricks. | Dependence on Technology: The machine requires a certain level of technical knowledge and expertise. |

| Consistency: It involves laying bricks in a consistent and uniform manner. | Reduced Employment Opportunities: It may lead to a reduction in employment opportunities for human workers. |

Cost of Automated Bricklaying Machine

These machines can cost anywhere from tens of thousands to hundreds of thousands of dollars. Furthermore, other factors to consider when evaluating the cost of these machines include maintenance, repairs, and the cost of training personnel to operate them.

Conclusion

Automated Brick Laying Machine is a significant advancement in the construction industry. It improves the efficiency and quality of work. Furthermore, it also reduces the construction time of structures. There are different kinds of automated bricklaying machines. The selection of machine depends upon multiple factors like the scale of projects, labour needed, etc. Furthermore, as everything has advantages and disadvantages, the automatic brick-laying machine has them. Lastly, the cost of an automated laying machine depends upon a variety of factors as discussed above.

1 comment

Pervious Concrete Advantages and Disadvantages

[…] Hyperlink: Automated Bricklaying Machine in the World […]