Whether you’re a homeowner or own commercial property, investing in a roof is a deal. While people often focus on roofing materials, like shingles, underlayment, and ventilation systems, they overlook the importance of roof flashing. However, it protects areas of your roof—like valleys, chimneys, vents, and skylights—from water damage. Thus, it is important to know about the types of roof-flashing materials. Choosing the material for your roof-flashing is essential, for ensuring its durability and effectiveness. In this blog, we’ll explore types of roof-flashing materials with relevant data to discuss their pros and cons.

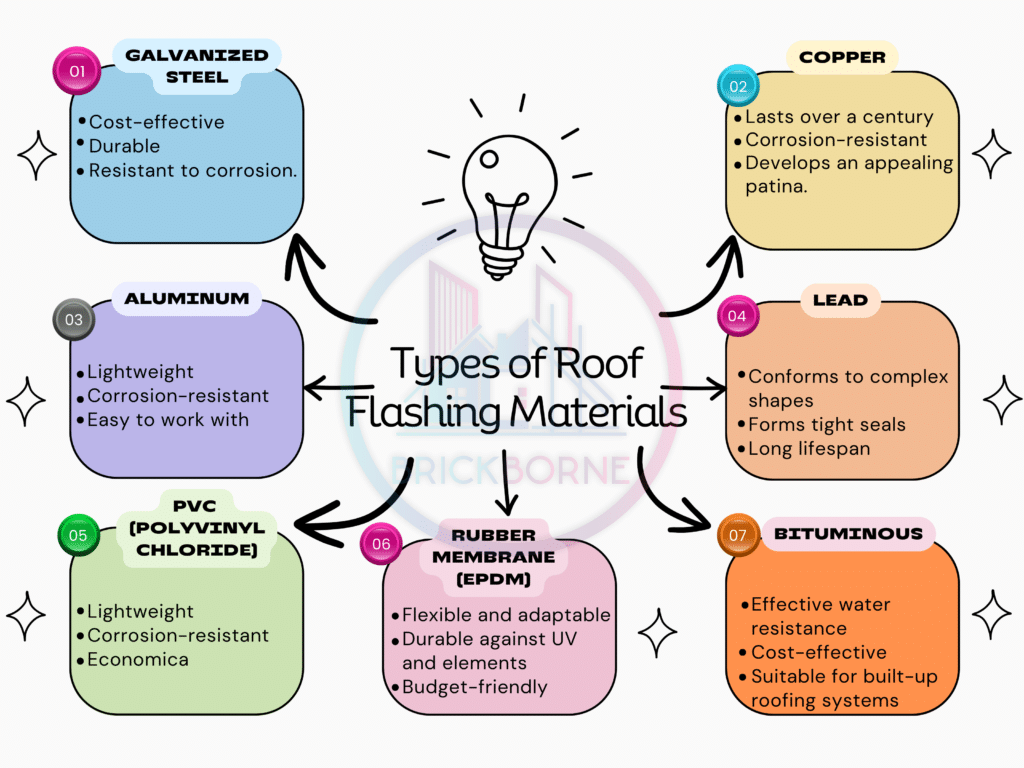

Following are 7 important types of roof-flashing materials:

1. Galvanized Steel:

When we talk about types of roof materials for flat roofs, galvanized steel is one of the options that you can consider. It has a protective zinc coating that helps prevent corrosion making it very durable and resistant to weather conditions. That’s why People often use this type of material in valleys and around chimneys.

Advantages

- Galvanized steel is a cost option.

- Historical data indicates that people have long recognized the durability of galvanized steel.The zinc coating provides resistance, against corrosion.

- You can use it for roofing applications.

Disadvantages

- If the zinc coating becomes damaged, galvanized steel can gradually rust..

- It might not have the visual appeal that other materials have.

- Industry data shows that galvanized steel is a widely preferred choice, making up approximately 40% of all roof-flashing materials used in the United States.

2. Copper

Copper flashing is famous for its appearance and long-lasting nature. Many people choose it for its beauty and the charming patina that develops over time making it a popular option while selecting suitable types of roof-flashing materials, for buildings and upscale residences.

Advantages

- Studies show that copper flashing can endure for more than a century.

- Secondly, Copper exhibits resistance to corrosion.

- As time goes by copper develops an appealing patina.

- Lastly, With the minimal upkeep required copper maintains its allure.

Disadvantages

- The initial cost of copper flashing tends to be higher compared to other options.

- Copper carries a risk of theft due to its value as scrap metal.

- It is important to have skilled craftsmen install copper flashing properly.

- Based on data, it is observed that 10% of residential roofing projects utilize copper flashing, particularly in high-end or historical areas..

3. Aluminum

Aluminum flashing is a choice, for roof flashing because it is lightweight and resistant to corrosion. People commonly use it around areas like dormers, skylights, and other roof openings.

Advantages

- Firstly, Aluminum is easy to work with and install.

- Aluminum naturally resists corrosion.

- Aluminum flashing is easy to handle and it can be adapted to needs.

- It provides an option compared to materials.

- Lastly, Overall aluminum flashing offers benefits that make it a practical option, for roof protection.

Disadvantages

- Firstly, Periodic inspections and maintenance may be necessary.

- Last but not least, people use aluminum flashing in approximately 20% of residential roofing projects due to its balance of affordability and corrosion resistance, as shown by the data.

4. Lead

For ages, lead flashing has been an option, for roofing due to its flexibility. It can easily adapt to shapes and create a flawless seal. Therefore, people often use this type of flashing in roof valleys and around chimneys.

Advantages

- Firstly, lead flashing readily conforms to complex shapes for superior sealing.

- Secondly, Statistics show that lead flashing forms tight, long-lasting seals.

- Lead flashing boasts a long lifespan and is resistant to corrosion.

Disadvantages

- Lead flashing can be quite weighty, so it requires support during installation.

- Concerns may arise regarding the use of lead in roofing materials, which is why it is advisable to hire professionals for installation.

- To minimize any health risks, it is advisable to have experts handle the installation of lead flashing.

- 10% of roofing projects still incorporate lead flashing because of its sealing capabilities.

5. PVC (Polyvinyl Chloride)

PVC flashing has become increasingly popular because it is affordable and resistant to moisture. People commonly choose it in regions where corrosion is a concern, especially in coastal areas.

Advantages

- Lightweight PVC is known for its lightweight nature.

- It provides protection against corrosion.

- PVC is an economical option.

- PVC requires less maintenance.

Disadvantages

- Flashing materials may not have the longevity, as other metal alternatives.

- Prolonged exposure to ultraviolet rays can potentially impact the durability of PVC flashing.

6. Rubber Membrane (EPDM)

Rubber membrane flashing, typically composed of EPDM (Ethylene Propylene Diene Monomer), is a flexible and durable option commonly used around roof penetrations like vents and pipes.

Advantages

- Rubber membrane flashing is known for its flexibility and adaptability.

- It demonstrates impressive durability, against UV rays and the elements.

- Installing it is a straightforward process.

- It offers a budget-friendly option.

Disadvantages

- Some may find that rubber membrane flashing lacks the appeal of metal flashing.

- The quality of rubber membranes can vary among manufacturers potentially affecting their longevity.

- 5 to 10% of roofing projects utilize EPDM rubber membrane flashing, primarily due to its flexibility, which makes it an attractive choice, for roofing applications.

7. Bituminous

Bituminous flashing, also known as asphalt flashing, comprises layers of asphalt-saturated felt and asphalt cement. It is frequently employed in built-up roofing systems and around chimneys and vents.

Advantages

- Bituminous flashing is highly regarded for its ability to keep water out.

- It’s a cost option that won’t break the bank.

- Works perfectly with built-up roofing systems.

Disadvantages

- You may need to perform regular maintenance and resealing from time to time.

- It may not match the longevity of metal flashing materials.

- In around 10 15% of roofing projects, bituminous flashing remains a choice for its effective waterproofing capabilities, in specific applications.

After reading this article, you may now have a good understanding of the types of roof-flashing materials. The selection of the right types of roofing material for flat roofs plays an important role when investing in roofing systems. Each type of flashing material possesses its own set of advantages and disadvantages.

For those who prefer long-lasting choices, galvanized steel and copper flashing materials are options. Aluminum and PVC flashing provide both corrosion resistance and affordability while lead flashing is highly effective, in sealing capabilities. Rubber. Bituminous flashing offers solutions that cater to specific roofing needs.

Regardless of the material you choose, it is crucial to have your roof flashing professionally installed and regularly inspected. By understanding the characteristics and data associated with types of roof-flashing materials you can make a decision that ensures the protection and longevity of your roofing system. This will safeguard your investment for years to come.

1 comment

Liquid EPDM

Wow. Amazing blog. I always like such kind of informative posts. The way you have mentioned every material specification is great. Well, I like EPDM the most as it gives me the best outcomes. EPDM butyl liquid rubber roof is different from other roofing materials due to its versatility, durability, cost effectiveness, and extreme weather resistance properties. EPDM rubber roof is a synthetic rubber material that is known for its durability and resistance to weathering, making it an excellent choice for roofs that are exposed to harsh weather conditions. I also had my best experience with EPDM butyl liquid rubber roof coating that gives me further premium protection from all kinds of external harmful elements.